TURNTABLE & TURNOUT

Turntables and other turnouts enable the introduction and removal, the distribution of conveyed goods in tight spaces and the merging of conveyor lines. The position of the conveyed material can be changed to ensure an optimal position for further processing.

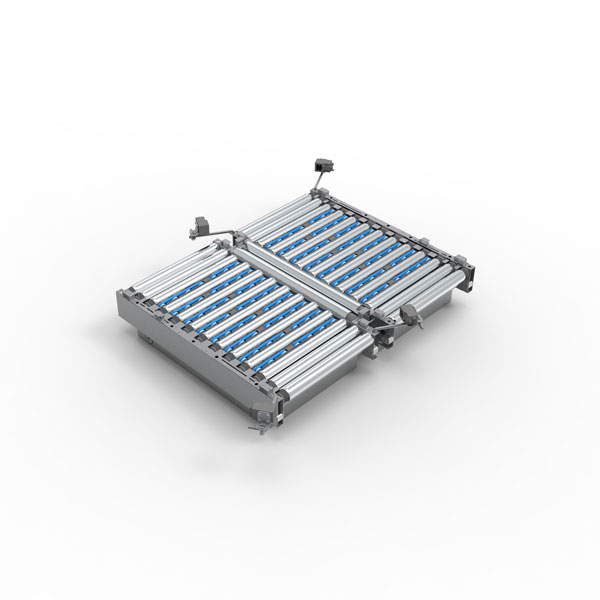

BS-HSM 1002

High Speed Sorting Module

The high-speed sorting module is responsible for the rejection of conveyed goods from a roller conveyor – with an angle of up to 90°. The direction (left/right) is freely selectable. The BS-HSM 1002 can be composed of several modules that can be controlled independently of each other. A retrofit of the high-speed sorting module to our roller conveyor BS-RF 2030 is possible. In combination with our driven roller gusset BS-AR 1001, the formation of a switch is no problem.

| Payload (max.) | 50 kg |

| Ambient temperature | -5 to +40 °C |

| Surrounding area | Production and storage halls |

| Nominal widths |

400–450 mm 600–650 mm 800–850 mm 1000–1050 mm |

| Roll division transverse to the conveying direction | 60 mm / 75 mm / 90 mm |

| Swivel angle | Max. +/- 45°, optionally 90° left, right or on both sides |

| Pan time | 0,4 s |

| Power of the drives | 40 W; Connection 24 VDC |

| Speeds (max.) | 1,5 m/s to max. 35 kg |

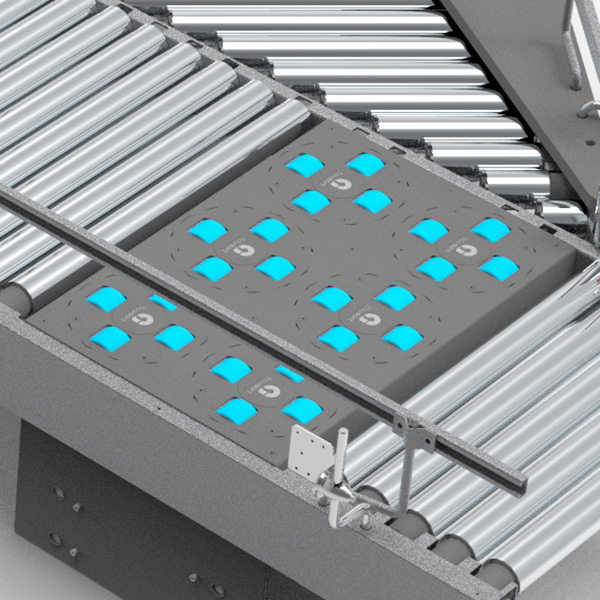

Belt converter

BS-RU 1003

The BS-RU 1003 is a belt stroke converter and is suitable for the infeed and unloading of conveyed goods. The conveyed material is discharged at a 90° angle. The BS-RU 1003 is characterized by a robust and durable construction. It is delivered mounted and pre-wired. The scope of delivery includes light barriers, control modules and supports.

| Payload | 50 kg per storage space |

| Ambient temperature | +5 to +40 °C |

| Surrounding area | Production and storage halls |

| Nominal widths | 350 to 1.000 mm |

| Stroke | 20 mm (10 mm above/ 10 mm below the conveying) |

| Lifting movement | Eccentric stroke |

| Roll diameter | 50 mm |

| Transition | From roll to roll using poly-V belts |

| Specifications | C-profile frame, powdered, RAL clay as desired |

Merging & Diverting

Conveyors

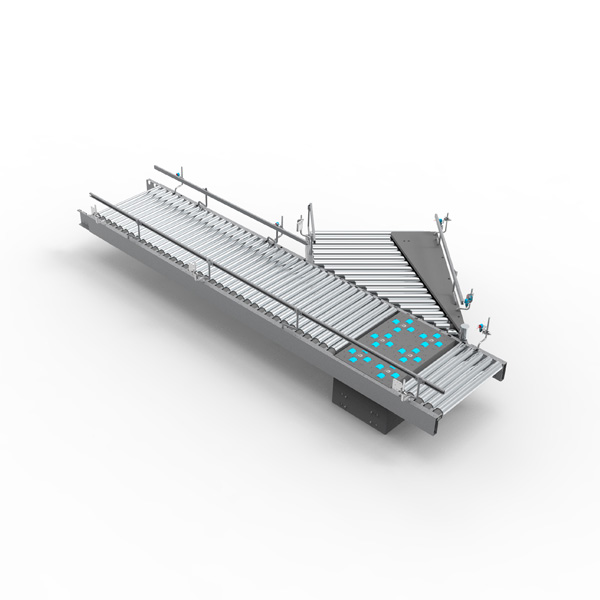

BS-AR 1001

A motor roller drive is installed in this driven roller gusset, which drives further rollers by means of poly-V belts. As a result, two conveyor lines can be merged. The roller gusset can also be used as a turnout, e.g. with the help of our high-speed sorting module BS-HSM 1002. The driven roller gusset BS-AR 1001 is the ideal complement to our roller conveyor BS-RF 2030.

| Payload (max.) | 50 kg per storage space |

| Ambient temperature | -5 to +40 °C |

| Surrounding area | Production and storage halls |

| Nominal widths | 350 to 1.050 mm (other widths on request) |

| Roll pitch | 60 mm |

| Angle | Standard 30°, 45°, 60° – special dimensions on request |

| Version | Left/right |

| Roller type | Support roller with plastic bearing bottom and ball bearing / Poly-V belt |

| Roll diameter | 50 mm |

| Rollenmaterial | Steel galvanized |

| Power of the drives | 40 W; Connection 24 VDC |

| Speeds (max.) |

60 m/min at max. 35 kg; 48 m/min at max. 50 kg |